Home » Warehouse Racking Installation

Warehouse Racking Installation

Warehouse racking installation from the UK’s principal manufacturer of pallet racking.

When choosing a pallet racking installer, it’s important to choose an experienced provider with the necessary technical know-how to get the job done right first time. Here at RediRack, we have over 50 years experience in the supply and installation of warehouse racking.

As the UK’s principle manufacturer of pallet racking, we offer end-to-end project management that includes manufacture, supply, installation and ongoing maintenance.

With full SEMA membership, all of our racking installations are carried out in full accordance with SEMA Codes of Practice and Health and Safety Regulations, ensuring a safe and compliant installation first time, every time.

Warehouse Racking Installation From a SEMA Approved Company

When choosing a pallet racking installer, it’s important to choose a company that is fully accredited under SEMA. SEMA are the UK’s governing body for the storage industry, setting the standards for safe and compliant storage solutions. That’s why it’s reassuring to know that when you choose RediRack, you’re choosing:

- SEIRS-Accredited Installers: With full SEMA membership, our team of pallet racking installers are all certified under the Storage Equipment Installers Registration Scheme. This ensures each of our installations are carried out to the highest of industry standards.

- Safety-led installation: Our warehouse racking installations are carried out as safely and efficiently as possible, in full accordance with SEMA Codes of Practice to ensure the safety of your workforce.

- Stock and Asset Protection: By putting safety first, we protect your investment and your valuable stock.

- Full Regulatory Compliance: We keep your business fully compliant with all UK Health and Safety laws, for greater peace of mind.

- SEMA Approved Racking Inspectors (SARI): Once the installation is complete, our fully certified SARI inspectors will check the load-bearing capacity of your racking to ensure it is safe and ready for immediate use.

- Dedicated Aftercare: Our SARI Inspectors can also arrange annual racking inspections and ongoing maintenance agreements with you to keep your racking in peak condition. This ensures reliable and safe performance for years to come.

Why Is It Important To Choose a Certified Racking Installer?

Choosing a non-certified provider can lead to poor installations which do not fully comply with all Health and Safety regulations. This can result in structural failures, costly damages, and threats to the safety of your workforce.

Unfortunately, there are many installation companies out there which do not possess full accreditation. It is therefore important to select the right provider, otherwise you will be leaving your stock, your staff, and your business exposed.

Can I Install My Own Pallet Racking?

Installing your own pallet racking is not recommended. This is because, for all of the above reasons, you could be putting both your staff and your business at serious risk. Not only could something go wrong during the installation process, but you will also be at risk of breaching UK Health and Safety laws if you don’t conduct a thorough on-site risk assessment.

Failure to identify hazards could lead to serious injury to your staff. It could also lead to structural failures in future, resulting in thousands of pounds worth of damage costs, both to your stock and to your racking systems. Your business could then be liable to legal penalties, potentially resulting in hefty fines and damage to company reputation.

RediRack's Warehouse Racking Installation Process

End-to-end Project Management

Here at RediRack, we’re more than just pallet racking installers. We offer complete, end-to-end project management for your warehouse storage requirements. By offering everything in-house, from initial design to manufacture, supply and install and ongoing maintenance, we save you from the hassle of having to manage multiple contractors.

By having a single point of contact, you can relax knowing that your project is being handled by seasoned industry experts who have handled similar projects for over 50 years.

Our technical knowledge is second to none, and we pride ourselves on offering flexible, tailored solutions for clients across a broad spectrum of industries. Want to find out what RediRack’s warehouse racking installation process involves? Read on to find out more:

Free Site Survey and Needs Assessment

Our pallet racking installation process starts with a free site survey. One of our racking experts will visit your premises to carry out an assessment of your site’s spatial requirements.

We’ll evaluate ways that you can get the most out of your warehouse space, and recommend specific racking solutions using our years of industry experience.

We will also organise a consultation with you to gain a greater understanding of your unique business needs and operational goals. This will allow us to design and supply you with a system that is 100% tailored to your needs.

Conveniently located in the West Midlands, we are strategically positioned to come to you to carry out your free site survey, no matter where you are based in the UK.

Design and Layout Planning

Next, once you’re happy with our proposed recommendations, we’ll get to work on designing a bespoke racking system that’s 100% tailored to your space. This includes planning a unique warehouse layout with you that’s specifically designed to enhance your workflows.

We’ll take into account everything from your warehouse space and budget, to your individual business goals. This ensures our pallet racking systems don’t just maximise storage space in your facility, but also enhances your business productivity.

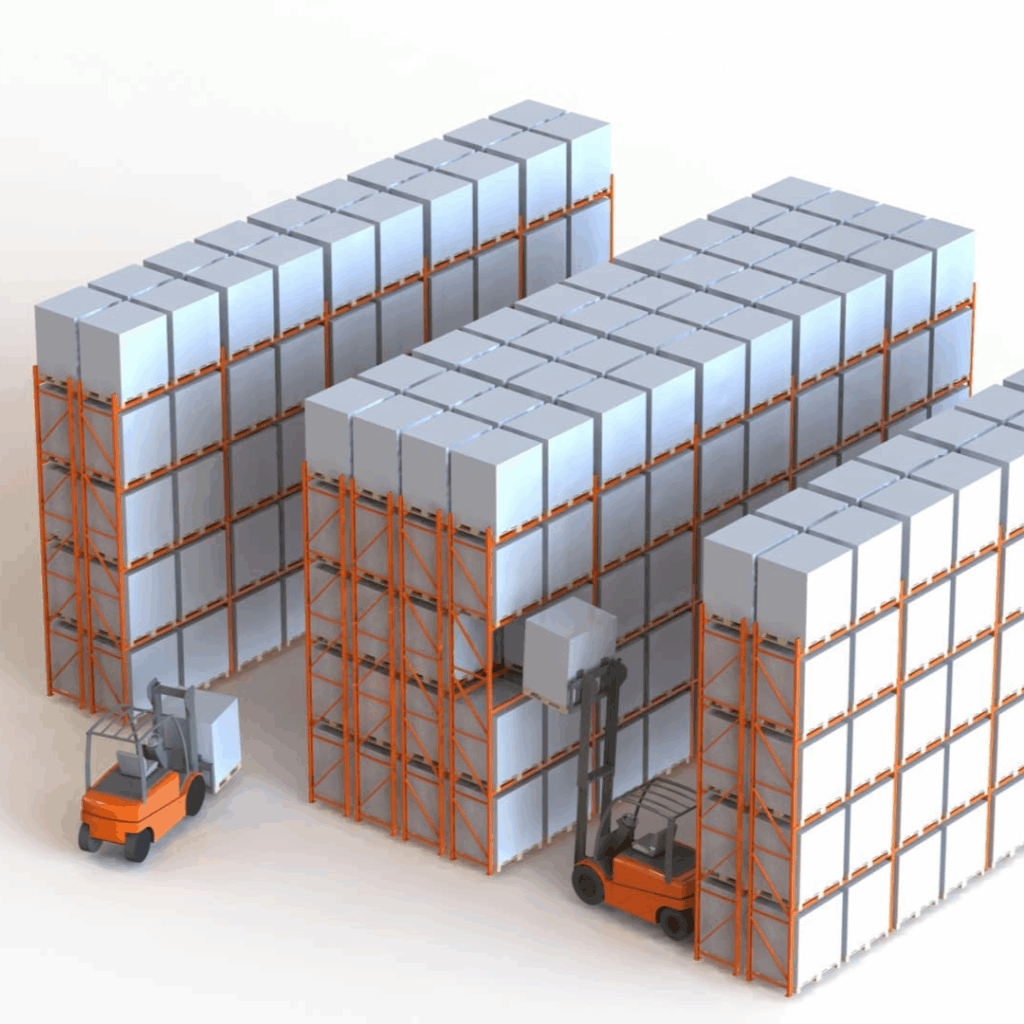

Using CAD 2D and 3D designs, our engineers will design a system that incorporates everything from racking beams and frames, to appropriate aisle widths for forklifts, picking and packing stations and more.

Racking systems we design include narrow aisle racking, wide aisle, drive-in, double deep racking and more. Discover our full range of pallet racking systems here.

Manufacture of Components

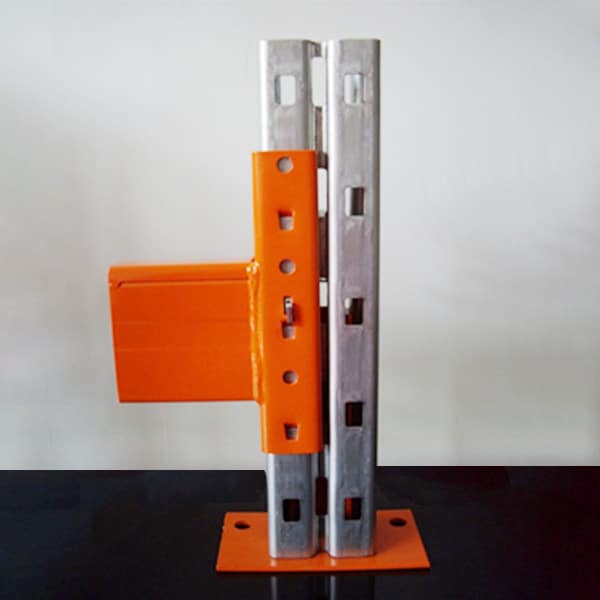

Layout and designs approved, we’ll get to work on manufacturing your bespoke pallet racking system. Established in 1973, our state-of-the-art manufacturing hub in Cannock has been manufacturing high-strength pallet racking for over 50 years.

By opting for a pallet racking installer that manufactures their own racking, you can be assured that rigorous quality controls have been implemented along every stage of the production process.

Built from the finest quality British materials, our steel frames and beams are incredibly strong and durable, ensuring your pallet racking is built to perform reliably for years to come.

Our trademark RediRack pallet racking has a reputation for being some of the strongest pallet racking in the industry. We specialise in robust, heavy duty pallet racking specifically engineered to bear heavy loads.

Professional Risk Assessment

Installing or updating pallet racking introduces new hazards that aren’t part of everyday warehouse operations. That’s why completing a risk assessment before installation is essential if you wish to remain compliant with the Health and Safety at Work Regulations 1992.

Our SEIRS-registered pallet racking installers can conduct a thorough on-site risk assessment at your facility to protect your workforce and your stock.

We will work closely with your Health and Safety Officer or Warehouse Manager to identify site-specific risks, implement control measures, and develop a safe working plan during installation.

Once the installation is complete, we will also update the assessment to cover your new system, ensuring ongoing compliance and a safe working environment.

Pallet Racking Supply and Install

Finally, we’ll get to work on installing your new pallet racking system. Our SEIRS-registered pallet racking installers carry out all installations in full accordance with SEMA Codes of Practice, ensuring strict adherence to the highest industry standards.

By choosing a pallet racking installer that manufacturers their own racking, you’ll also be choosing a provider that knows their product inside and out.

From the design specifications to the load capacities, our deep familiarity with our trademark RediRack pallet racking ensures a flawless installation process every time.

Our process covers everything from the installation of individual racks and safety products, to the mitigation of risks as identified by the risk assessment. Our team will work quickly and effectively to minimise downtime to your operations.

Final Inspection and Ongoing Maintenance

Our end-to-end service doesn’t stop once the installation is complete. We’ll carry out post-installation load-bearing tests to check your racking system is fit for purpose and is ready to start performing reliably straight away.

Our SEMA-Approved Racking Inspectors can also arrange annual warehouse racking inspections with you to ensure your systems remain in peak operational condition.

Combined with our pallet racking repairs and maintenance services, we offer comprehensive aftercare for our clients to ensure their investment is protected.

This also ensures long-term safety of staff, full regulatory compliance, and a pallet racking system built to perform reliably for years to come. With RediRack, you’re not just installing racking, you’re gaining a partner committed to the long-term success of your business.

Pallet Racking Supply & Install: Why Choose RediRack?

✅ Space-maximising Solutions: Our systems are designed to make use of every inch of your facility, maximising the storage capacity of your warehouse.

✅ Strength & Durability: Manufacturing all of our pallet racking in-house, quality isn’t just an option; it’s a guarantee.

✅ Load-bearing Capacity: Strong, durable construction allows you to store large quantities of stock, including items of different sizes and weights with ease.

✅ Fully Adjustable Designs: Fully adjustable uprights and beams provide a flexible, scalable racking system that can be re-configured as your business grows.

✅ Cost-effective Solutions: Space-efficient designs maximise storage capacity and speed up turnaround times, helping you reduce costs over time.

✅ Industry Compliance: All our installations meet SEMA Codes of Practice, guaranteeing compliance with the highest industry standards.

✅ End-to-End Services: From concept to completion, we handle every stage of your racking installation. This gives you one point of contact, ensuring seamless and reliable project management.

Warehouse Racking Installation UK

Get a Free Quote Today

So for an end-to-end warehouse storage solution, get in touch with the industry experts at RediRack today.

Our friendly team will be ready to help assist you with your queries, provide you with a bespoke, no-obligation quotation, or arrange your free site survey at your facility.

Our Address

Bettys Lane, Norton canes,

Cannock, Staffordshire,

WS11 9NZ